Prepregmachines

Silverdale Enterprise Centre, SILVERDALE ST5 6SR UK

'SIMPLE IS THE HARDEST TO DO'

- LOW COST SIMPLE, EASIEST MOVE, PLUG AND PLAY, AND MINUTES TO START UP

- ONE PERSON, OPERATION 5 KILOS- 1000 KILO PER SHIFT

- NO MAINTENANCE FOR LIFE

- NO DELIVERY CHARGES.

- ALL PARTS NON-CORROSIVE –BEST QUALITY STAINLESS, ALUMINIUM AND ENGINEERING PLASTIC

- NO ROLLERS TO CLEAN - JUST A QUICK WIPE OF A PTFE SURFACE

- NO FINGER OR HAND TRAPS - 100% SAFE

- MOVING PARTS REMOVED FOR ADDED SAFETY ADDED EFFICIENCY, AND SIMPLICITY.

- NO TRAINING, VIDEO AND DIAGRAMS SUPPLIED.

- LIGHTWEIGHT 150 KGS CASTORS FOR EASY MOVEMENT.

11. MOST RESINS AND REINFORCEMENTS

12. 4 TO 6 WEEKS DELIVERY FROM CLEARED FUNDS

FREE DELIVERY

CRATED, DELIVERED TO YOUR NEAREST HUB - ALL CUSTOMS AND LOCAL FEES TO BE PAID FOR.

NO MORE THAN

£25,000 ('B' STAGE)

Cut Time -

Training on our Carbon fibre prepreg machines takes 2 hrs or less instead of 3+ months on standard machines. Quicker Simple one operation cleaning and rebuild, quicker process turn around, Split Frame for rapid extension/implant. Plug and play same Day as delivery.

Save Money -

Lower Labour needs, no maintenance, no computers, robust. Hand tool modifications.

Made Simpler -

Failsafe - Simple to operate, unskilled labour, hand tools instead of cutting and welding.

Made Better -

Movable, Adaptable, easy to reconfigure and change materials, better Windon, robust.

Made to Work -

Over 60 years in composites and special purpose machines, 35 years research and developing PrePreg Machines daily, over 600 hours Value Engineering (Over Lockdown).

Make Safer –

no traps like larger rollers, cleaners always take risks with other machines, no moving parts at the impregnation stage Windon on release remote from rotating parts, remote machine controls as well as multiple stop buttons. Only 13amp power needed.

Made Easy -

No Computers, hand tool construction enabling quick process change, using frame inbuilt keyways. Doctor boxes slot together like Meccano – no bolts or fasteners.

Made to Budget -

We do not cut corners to maintain prices, we look to cut out waste and improve efficiency, all areas have been brainstormed to cap costs and maintain budgets.

Precisely Made -

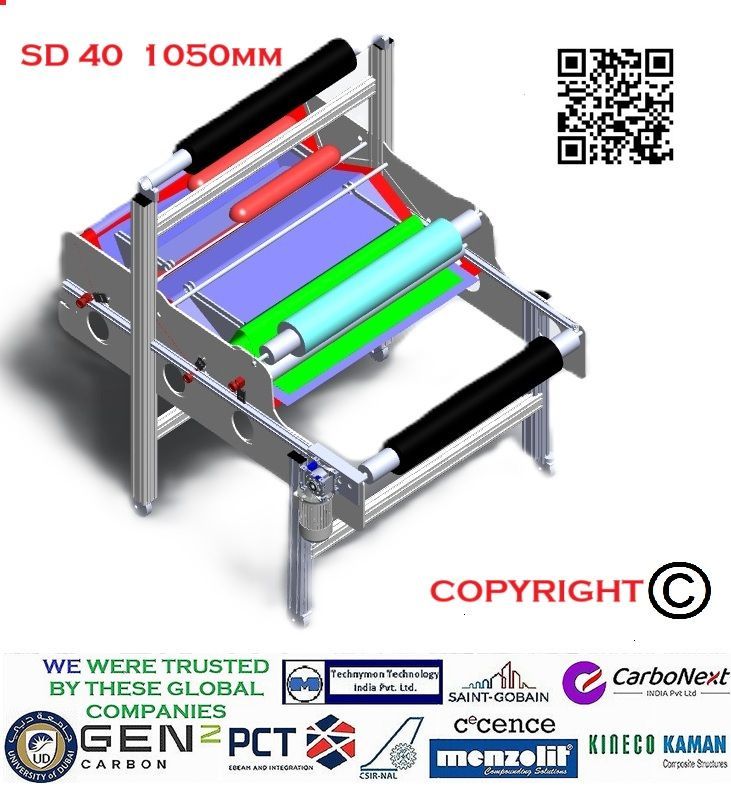

Designed on CAD, DXF output to CNC machine cutting. Maintenance Free - Sealed for life bearings, no software failures, nothing to break, bend or jam. Made to be the Best! - 35 years intense 7 days a week Research and Development trials – scrapping up to 1 tonne of composites a week! Over 600 hours of Value Engineering, every millimetre scrutinised minutely for improvement, constantly and repeatedly.

Corrosion Proof -

Aluminium frames, Polypropylene, Laminated Glass, Stainless Steel and PTFE Doctor boxes.

Modular -

Locating keyway slots, hand tools, Hot Melt, Roving Cutter/Spray, Creels, Preheat, Process IR heat, Advanced PrePreg Process, cooling fans, cooling plates, Multiple layers, Unlimited Line extensions/Implants.

Technical Back UP -

Online Support within hours, 24/7 Manufactured - UK assembled or DIY, Local Design and Cad Design.

Contact Us Today!

About Simply Prepreg Machines, Simple, Intelligent Innovation, Precision Engineered. We provide 3 widths of, SMC, Carbon fiber Prepreg, Hotmelt Prepreg multi process machines in fact for most materials.

Simply Designed -

Made by indentured Boffin, Old school apprenticed, at Proof and Experimental establishment Eskmeals and Royal Ordinance Factory Patricroft, attained a prize for one of the highest City and Guilds Full technology Certificates in the Union of Cheshire and Lancashire Institutes - Not a degree yes, but hands on practical Engineering.

Cut Cost –

Simple PrePreg Machines for Initial Purchase price up to 100th of our competitors’ cost. Designed to your budget. Quick Modular Process turnaround – no mechanical lifting devices only hand tools, Single person operation up to 1 ton of composite per day. Low-cost spares and repairs (local companies – off shelf). Sectioned frame for low-cost extensions/Implants to the line. No Maintenance. On castors for single person repositioning, no cranes, or forklifts.

For more than 40 years,

Boffin George has created Special machine projects of all sizes, for a wide range of Industrial clients. He loves what does and is only satisfied when you are too. Composites is his passion and our business.

Give us a call or send us an email

We’ll Immediately respond. We will instantly give you a full response with 60 years of unmatched experience, discuss your dream machine and give you an estimate, within your budget, on time and ready to plug and play.

Taught by the world’s best brain on secret aerospace and Plastics technology

On a 1 to 1 basis for 3 years resulting in many world firsts at a fraction of the cost of our competitors.

A spell as a technician at Manchester University,

Start-up Triton Plastics on aerospace hot press moulding,

Then ERF Plastics SMC mouldings Technical Representative for transport mouldings,

Advising Senata Group in Germany,

followed by Menzolit as a consultant on new formulas and processes.

Branching out on my own GRP mouldings, and prepreg was the order of the day.

During the day,

CAD work was undertaken on special purpose machines, conveyors, and mechanical Engineering designs, in the evenings my spare time was spent developing PrePreg machines. Several sales enabled me to spend full time from then on. About 35 machines have been made, each one being vast improvement to the one before